Promoting Environmentally Friendly Containers

“In China, the demand for packaging in the logistics industry is very high,” reports Wang Guixin. As director of the Qingdao Junshengmingshi Logistics Packaging Institute, she knows what she’s talking about.

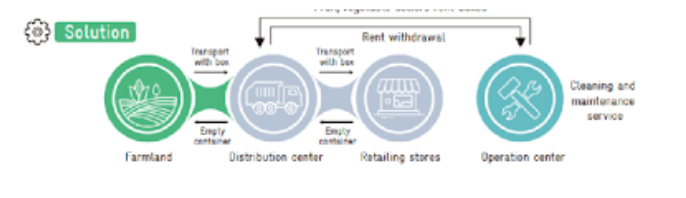

The transport of fruit and vegetables alone in the city of Qingdao accounts for more than 17 million boxes every year. These boxes, which are resource-heavy in their production and disposal, are used only once. Guixin explains: “If the packaging can be replaced by reusable options, the amount of single-use plastics could be significantly reduced at source. Containers can be circulated from the farms via the distribution centre to the retail stores.” It is this green and sustainable approach that was the focus of our pilot project. Our aim: to develop an environmentally-friendly circulation system for fruit and vegetable boxes in the Qingdao West Coast new area. This led to changes to traditional packaging at the source, thereby promoting the development of green packaging, and reducing packaging, pollution and recycling. In short: a business model for the future.

WHAT HAVE WE ACHIEVED IN 12 MONTHS?

1. Use and re-use again and again and again…

Together with our partners, we developed reusable containers to replace disposable packaging products. Designed to meet modern technical standards, these ‘turnover boxes’ are durable – for a long life span – and foldable – for efficient transport and storage. The base material of the box body meets the food-grade safety standard. By testing 60,000 reusable containers to bring fruit and vegetables from farms to retailers for 12 months, we have been able to reduce disposable packaging materials by 120 kg per box while additionally saving more than 500 liters of water annually. The improved design means that food gets less damaged during storage and transportation – the damage rate dropped from 35% to almost zero. Also, food does not need to be re-packed during transport, as is usually the case with disposable boxes. According to research data, re-packaging on the way to the retailer usually results in a 20% food loss. Using reusable containers brings this rate down to almost zero, and can save 300 kg of fruit and vegetables per year. In addition to the environmental benefits, there is a clear financial argument in favour of the new boxes: the daily cost of a reusable container is 1 Renminbi – compared to 600 Renminbi for a new single-use one.

2. Going digital

We created an intelligent management platform to track the turnover boxes from their origin to their destination. Using the digital system, all actors along the chain can follow the turnover boxes, their code, load, place and time of shipment, up until receipt. The boxes and their contents are clearly traceable, so that users can be assured that their delivery is guaranteed.

3. Green financial services

In this pilot project, we explored a large-scale circulation scheme through financial leasing, bringing the industry and finance sectors together. The Qingdao Construction bank included the pilot project into its green finance support scheme portfolio and provided a 10 million Renminbi loan to enterprises which lease the reusable containers. This sound financial cooperation proved to be the solution for a bottleneck for enterprises wanting to use the turnover boxes.

4. Policy support

With research findings now available on their environmental and economic benefits, the reusable containers can be promoted as a sustainable business model. The scheme will benefit from the strong support of governments on all levels, such as national ministries and commissions, provincial and municipal governments. The National Development and Reform Commission and the Ministry of Transport have successively visited the project area and, together with eight other departments, jointly issued a notice on accelerating the promotion and application of standardised logistics turnover boxes to the whole country, formally promoting the pilot experience and model. The Ministry of Agriculture and Rural Areas visited the project area and recommended the project as an advanced model of agricultural product packaging to be applied in the industry as a measure to strengthen food safety. The Ministry of Industry and Information Technology rated the project amongst 71 excellent pilot units of “Made in China 2025”. The National Standardization Conference recommended the pilot project as an excellent case of national standardisation work in 2021.

WHICH EXPERIENCES FROM THE PILOT PROJECT CAN WE SHARE WITH OTHERS?

- Involve relevant financial institutions in the early stage.

- While the frequency of box usage is stable in the Qingdao pilot and is not affected by seasons, the costs related to seasonal changes need to be carefully considered.

- The deposit and property management are important for reusable containers.

- The digital system can improve management effectiveness and efficiency.

- It is vital to combine an information management system with financial instruments to support the project implementation.

Implemented by: Qingdao Junshengmingshi Logistics Packaging Co., Ltd

Documents